More Energy

Traditional Inverter |

SolarEdge Solution |

|

|

|

|

|

|

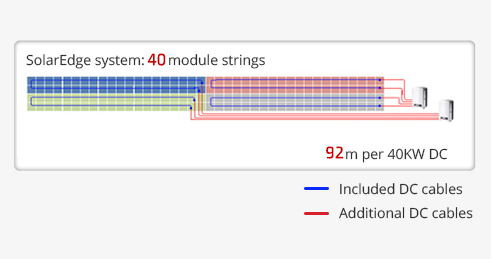

† Reduce BoS Costs

† Up to 11.25kWp per string >longer strings

-

Fewer strings

-

Less wiring, combiner boxes, fuses, etc.

† Up to 50% reduction in BoS cost†††

†††††††††††††††††††††††††††

†

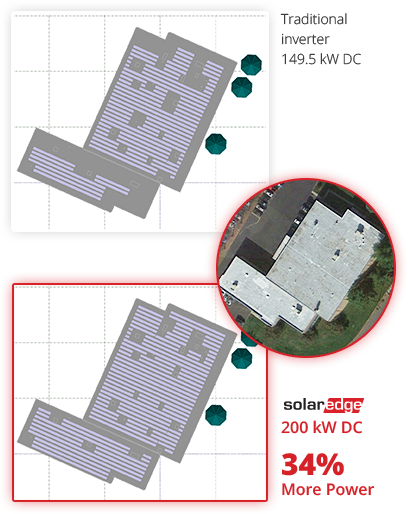

† More Modules

† Power optimizers enable installation of:

-

Modules in shaded areas

-

Strings of uneven lengths

-

Modules in multiple orientations and different roof facets in a single string

† More modules on the roof

† More power, More revenue

†

†† Cost Saving Maintenance

† Module-level performance monitoring & remote maintenance lead to:

-

Less trips to site

-

Less time spent on site

-

Higher system uptime

† Free module-level monitoring for system lifetime

† Real-time full insight to system from anywhere

-

Easy access via web browser and mobile device

†

†† Future Compatibility & Warranty

-

Low-cost inverter replacement out of warranty

-

40% less than traditional inverters

- SolarEdge flexible design allows modules of different power classes and brands in the same string

-

No need for expensive module inventory stocking

-

25-year power optimizer warranty, 12-year inverter warranty, lifetime free monitoring

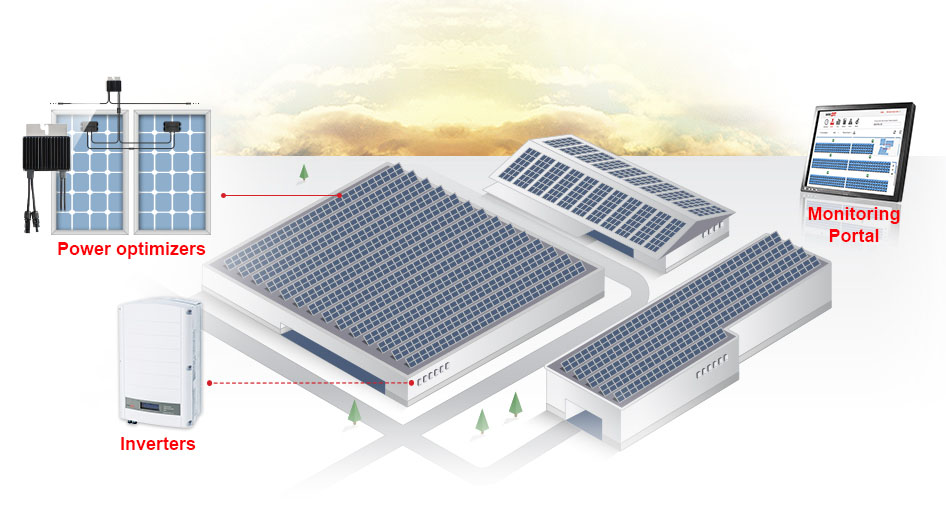

Commercial power

optimizers

Commercial power

optimizers600W, 700W

Commercial

inverters

Commercial

inverters15kW, 16kW , 17kW, 25kW, 27.6kW,

33.3kW

Monitoring

portal

Monitoring

portal

† Enhanced Safety

-

No high VDC during installation or maintenance - power optimizers and DC cables automatically de-energize when inverter is disconnected or grid power is shut down

-

Remote monitoring instead of diagnostics work at dangerous heights

-

Only inverter certified to IEC 60947 as a disconnection means and to VDE 2100-712

-

Better suited for future insurance requirements

†

†

† Motor Soft Starter

Soft starters can be set up to the requirements of the individual application.

A motor soft starter is a device used with AC electrical motors to temporarily reduce the load and torque in the power train and electric current surge of the motor during start-up. This reduces the mechanical stress on the motor and shaft, as well as the electrodynamic stresses on the attached power cables and electrical distribution network, extending the lifespan of the system.